Processing and Maintenance of Silicon-Carbide Crucibles- How to Maintain Optimum Performance

Processing and Maintenance of Silicon-Carbide Crucibles: How to Maintain Optimum Performance

Silicon carbide (SiC) crucibles are widely used in various industrial applications due to their high thermal conductivity, exceptional strength, and excellent resistance to chemical corrosion at high temperatures. Crucibles made from SiC are essential in metal casting, the production of semiconductors, and the processing of materials that require high-temperature conditions. However, like any specialized material, the performance and longevity of silicon carbide crucibles depend significantly on how they are processed, maintained, and operated. In this article, we will explore in detail the processing methods used to create silicon carbide crucibles, as well as the best practices for their maintenance to ensure that they maintain optimum performance throughout their lifespan.

Introduction to Silicon Carbide Crucibles

Silicon carbide crucibles are designed to withstand extremely high temperatures and aggressive environments. They are commonly used in industries like metallurgy, ceramics, and the semiconductor industry for processes such as metal melting, chemical processing, and crystal growth. Their excellent thermal shock resistance, combined with superior wear and corrosion resistance, makes SiC crucibles ideal for handling molten metals like aluminum, copper, gold, and various alloys.

Given the high demand for SiC crucibles in critical applications, it is essential to understand both their manufacturing processes and the steps necessary for maintaining their performance over time. By keeping a SiC crucible in optimal condition, businesses can improve productivity, reduce downtime, and avoid unnecessary costs associated with premature failure.

The Manufacturing Process of Silicon-Carbide Crucibles

1. Material Selection

The quality of silicon carbide crucibles begins with the raw materials. High-purity silica sand and petroleum coke are the most common raw materials used in the manufacturing process. These materials are chosen for their ability to form silicon carbide under the right conditions. The quality of the raw materials used directly impacts the strength, thermal conductivity, and durability of the final product.

2. Powder Preparation

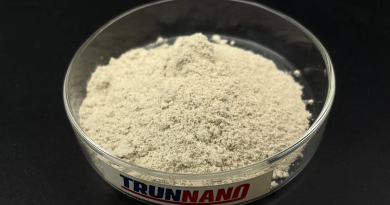

The preparation of SiC powder is a critical step in the production of crucibles. SiC powder is typically produced through the Acheson process, where silica and carbon are heated to very high temperatures (around 2000-2500°C) in an electric furnace. This process results in the formation of silicon carbide crystals, which are then ground to the desired particle size. A finer powder will result in a smoother and denser crucible, whereas a coarser powder may be used for different applications where a more porous structure is desired.

3. Molding and Shaping

Once the SiC powder is prepared, it is mixed with a binder to form a workable paste or slurry. This mixture is then molded into the shape of the crucible. Molding techniques vary, but the most common methods include extrusion, casting, and pressing. Each method has its advantages and disadvantages, depending on the size, shape, and application of the crucible.

– Extrusion: This method is often used for larger crucibles. The mixture is forced through a die to create the desired shape. This process allows for continuous production of crucibles with uniform shapes and sizes.

– Casting: For more intricate or complex designs, casting is used. The slurry is poured into molds and allowed to harden. This technique is useful for producing crucibles with intricate details or specific geometries.

– Pressing: In this method, the SiC mixture is placed in a mold and subjected to high pressure to form the crucible. Pressing is often used for smaller or more compact crucibles and ensures a dense final product.

4. Sintering

After the crucibles are formed, they undergo a process called sintering, which involves heating the molded SiC pieces in a furnace to a temperature just below their melting point (typically around 1500-1800°C). This step is critical as it helps the SiC particles bond together, forming a strong, rigid structure. The sintering process also reduces porosity, which enhances the crucible’s thermal conductivity and overall mechanical properties.

5. Finishing and Inspection

Once sintered, the crucibles undergo finishing processes such as grinding, polishing, and surface treatment. These steps ensure that the crucibles meet the required specifications for smoothness, uniformity, and surface finish. Any defects, cracks, or imperfections are carefully inspected and rectified before the crucibles are deemed ready for use.

Factors Affecting the Performance of Silicon-Carbide Crucibles

1. Thermal Shock Resistance

Thermal shock resistance is one of the most critical factors that impact the longevity of SiC crucibles. Silicon carbide crucibles are designed to handle rapid temperature changes without cracking or breaking. However, they are still susceptible to thermal shock if subjected to sudden and extreme temperature fluctuations. It is important to follow proper heating and cooling procedures to minimize the risk of damage.

2. Chemical Resistance

SiC crucibles are highly resistant to many chemicals, including acidic and alkaline substances. However, they are still vulnerable to certain corrosive environments, especially when exposed to molten metals with high chemical reactivity. Over time, exposure to corrosive materials can lead to surface degradation, which can affect the crucible’s overall performance. Regular inspection for signs of wear and tear is necessary to detect any damage early.

3. Mechanical Strength

The mechanical strength of silicon carbide crucibles is influenced by factors such as the quality of the raw materials, the sintering temperature, and the particle size of the SiC powder. Crucibles with higher mechanical strength are less likely to break under stress, making them more reliable for heavy-duty industrial applications. Regular checks for cracks, chips, or deformation are essential for maintaining mechanical integrity.

4. Thermal Conductivity

One of the key reasons SiC crucibles are chosen for high-temperature applications is their excellent thermal conductivity. However, over time, the crucible’s thermal conductivity may decrease due to surface oxidation or contamination from the materials it is exposed to. Maintaining the crucible’s surface and ensuring it is free from foreign particles is important to preserve its heat transfer capabilities.

Maintenance and Care of Silicon-Carbide Crucibles

Maintaining the performance of silicon carbide crucibles is a crucial aspect of their longevity and reliability. Below are some of the best practices for caring for and maintaining SiC crucibles:

1. Proper Handling

SiC crucibles are fragile and can break if dropped or mishandled. Always handle them with care during installation and removal. When transferring crucibles, use lifting tools such as tongs or cranes to avoid applying pressure to the crucible’s surface.

2. Preventing Thermal Shock

To prevent thermal shock, crucibles should be gradually heated and cooled. Avoid placing a cold crucible directly into a hot furnace, and always allow the crucible to cool down slowly after use. Rapid heating and cooling can cause internal stress, which may lead to cracks or fractures.

3. Regular Inspection

Perform regular inspections to check for any signs of damage or wear. Look for surface cracks, chips, or signs of corrosion, especially around the rim or base of the crucible. Any damage should be addressed immediately to prevent further deterioration or failure during use.

4. Surface Protection

Protect the surface of the SiC crucible from contamination. Avoid exposing the crucible to foreign materials that could affect its surface properties. After each use, thoroughly clean the crucible to remove any residues or debris. Using a soft brush or cloth, carefully wipe silicon carbide crucible suppliers down the crucible to prevent any abrasive damage.

5. Preventing Chemical Corrosion

While SiC is highly resistant to corrosion, prolonged exposure to certain reactive materials may cause degradation. Be mindful of the materials being melted or processed within the crucible. If the crucible is used with highly reactive metals or chemicals, it may need to be replaced sooner than expected. Periodically inspect the crucible for signs of corrosion or erosion.

6. Storing Crucibles

When not in use, store SiC crucibles in a dry, cool place, away from any direct heat sources. Avoid stacking crucibles on top of each other, as the pressure may cause them to crack or chip. If storing multiple crucibles, consider using protective padding or insulation to prevent direct contact between them.

7. Managing Usage Time

Every silicon carbide crucible has a limited lifespan, which is influenced by the frequency and intensity of use. For high-temperature applications, the crucible will degrade over time due to factors such as thermal cycling, corrosion, and mechanical stress. It is important to track the usage time of each crucible and replace them when they reach the end of their useful life to prevent unexpected failure during critical operations.

Conclusion

Silicon carbide crucibles are indispensable in high-temperature industrial applications due to their remarkable properties, including thermal shock resistance, chemical resistance, and mechanical strength. The performance and longevity of these crucibles are heavily influenced by both the manufacturing process and the ongoing maintenance efforts. By following best practices for handling, heating, cooling, cleaning, and inspecting these crucibles, industries can ensure their crucibles remain in optimal condition, leading to improved operational efficiency and reduced downtime.

Proper maintenance is essential for extending the service life of SiC crucibles and minimizing the risk of failure. By implementing the strategies outlined in this article, businesses can maximize the performance and reliability of their silicon carbide crucibles, thereby enhancing the overall productivity of their operations.

https://hearingearly.com/